Sandvik 253 ma is an austenitic chromium nickel stainless steel alloyed with nitrogen and reactive elements and suitable for a wide range of high temperature applications such as recuperators in steel mills and pci lances for blast furnaces.

253ma stainless steel data sheet.

The lean 11 nickel content of ra 253 ma is a key contributor to being cost effective and stable.

Ra 253 ma can decrease distortion and increase the service life of your equipment.

253 ma 153 ma fig.

It resists oxidation at temperatures up to 1150 c and can provide superior service to grade 310 in carbon nitrogen and sulphur containing atmospheres.

It has twice the strength as 309 and 310 stainless above 1600 f and great oxidation resistance up to 2000 f.

Furthermore sandvik 253 ma can very well take the place of higher alloyed materials such as 25cr 20ni steels and alloy 800h or even alloy 600 in certain cases.

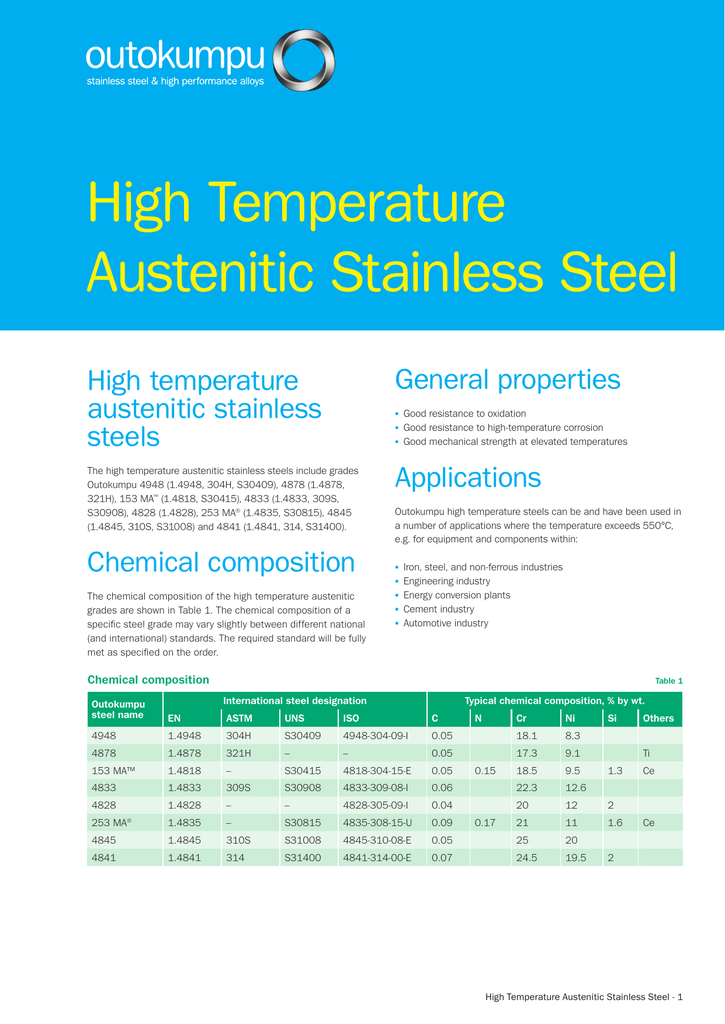

It should be noted here that 4948 contrary to the other.

Description alloy 253 ma 1 4835 is a heat resistant austenitic chromium nickel stainless steel.

The high strength heat resistant stainless steel ra 253 ma was developed over 30 years ago when the need for a heat resistant stainless steel with high strength while maintaining good oxidation resistance was present in the industry.

253ma is a lean heat resistant austenitic stainless steel developed for applications requiring high creep strength and good corrosion resistance.

Its balanced chemical compositions give this steel the optimum overall performance under temperature range of 850 c 1100 c and extremely high oxidation resistance.

Sandvik 253 ma is often preferred instead of stainless chromium steels which have insufficient creep strength and structural stability.

Ra 253 ma data sheet ra 253 ma has provided the solution to the demand for a heat resistant stainless steel with superior strength for over thirty years.

Atlas 253mais a grade combining excellent service properties at high temperatures with ease of fabrication.

High temperature austenitic stainless steel 5 creep strength figure 1 shows the relative creep strength for rupture after 100 000 hours as a function of temperature.

It resists oxidation at temperatures up to 1150 c and can provide superior service to grade 310 in carbon nitrogen and sulphur containing atmospheres.

253ma is a grade combining excellent service properties at high temperatures with ease of fabrication.

Neonickel alloys 253 ma an austenitic chromium nickel silicon grade 253 ma offers outstanding strength and unrivalled heat resistance.